Used Mining Crusher for Sale

The current mobile mining crusher for sale is fitted with the FL Smidt Raptor 300 Cone crusher. The unit has been packaged as mobile unit and is mounted on Wheels. The unit can be moved on WA roads, subject to issue of a permit.

The unit is offered with Full Hydraulic and lubrication package as well as the MCC panel.

To keep the Hydraulic and lubrication packages well maintained and clean they are mounted in a 20 Ft container along with the MCC.

Specification sheets supplied below for clarity.

For more specific needs or information please call us or email:

Joe 0427 548 853

Kieran 0476 548 853

Email support@littleindustries.com

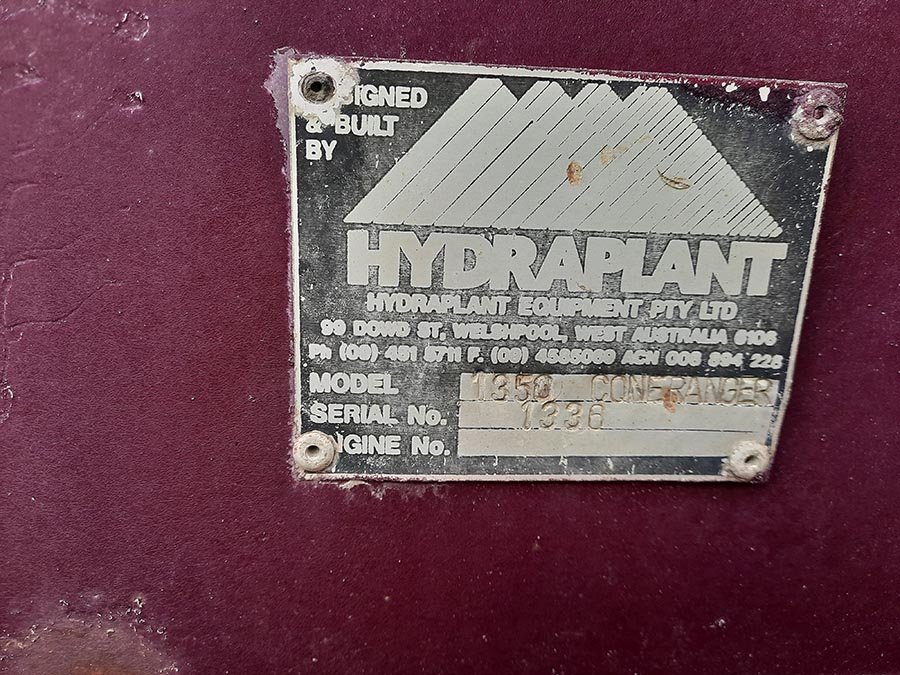

This mobile mining crusher unit for sale was Designed and built in Perth WA by Hydraplant Pty ltd. The machine is a wheeled mobile cone crusher with a FLSmidth Raptor model 300 cone crusher fitted. on it. The unit is all electric drive.

The Raptor Cone crusher was purchased in 2015 and fitted to the chassis in lieu of a Parker 1300 cone.

The unit comes complete with

Main chassis unit with Crusher and discharge conveyor

Electrical control and Lubrication cabin. This is mounted in a 20ft Container. This houses the MCC and the crusher control panel. In addition, the cone cru sher lubrication tank and the hydraulic power pack are also mounted in this container. The container is also fitted with an air conditioning unit.

Chassis

Fabricated steel beam chassis.

Width 3.0 M

Length 14.7 M

The mobile chassis is mounted on a Quad axle on the rear and a 5th wheel coupling for a dolly at the front of the unit. The unit can be moved on WA roads following acquiring of a WA main roads permit.

To allow ease of set up and stabilisation of the chassis the unit is fitted with robust supporting and jacking points.

Crusher

FL Smidt Raptor 300 Cone crusher.

300 HP Cone crusher unit. The raptor cone features bronze bush bearings with a force feed lubrication package.

The Overload protection and the adjustment package is fully hydraulic. The overload protection and tramp relief is carried out by series of hydraulic cylinders which clamp the upper frame to the lower mainframe.

Cone adjustment is via a screw thread bowl which is hydraulically clamped for operation.

Both the Hydraulic and lubrication packages are enclosed in a 20ft container.

Discharge conveyor

The discharge conveyor is 1200mm x 11.2 M long. Discharge height is 2.7 M.

Impact rollers are fitted in discharge zone of the conveyor. The remainder of the conveyor is fitted with 127mm x 430mm carry rollers.

Head drum is 340mm Dia with diamond lagging.

Conveyor is fitted with guards and lanyards.

MCC Enclosure.

The crusher MCC is also fitted in the 20ft container as well as distribution buzz bars for in coming mains or Gen set power.